Skip to content

World Class Fabricators Since 1976

World Class Fabricators Since 1976

Skip to content

World Class Fabricators Since 1976

World Class Fabricators Since 1976

Rochester Welding’s quality management system has been certified to meet ISO 9001 standards for manufacture, welding, and distribution of metal fabricated parts. The International Standards Organizations has assessed our production and customer support processes and has affirmed our dedication to continual quality improvement.

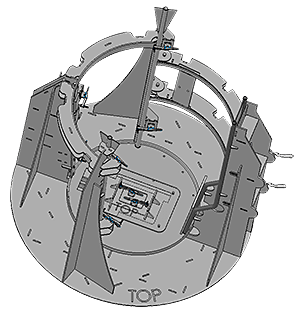

It’s more than just the metal. What Rochester Welding offers you only begins with our wide-ranging production capabilities and state-of-the-art fabrication equipment. We also help you ensure the quality of your metal parts with value-added design engineering support.

The Rochester Welding team skillfully applies the industry’s leading computer-aided design, manufacturing, and engineering (CAD/CAM/CAE) software utilities to your custom metal parts engineering needs:

![]()

![]()

![]()